Solar Heat for Industrial Processes

About the application

A solar thermal system for industrial processes is an innovative technology that converts solar energy into heat, in the form of hot water or steam, to support industrial processes and reduce fossil-based energy sources. It is also known as Solar Heat for Industrial Processes (SHIP).

Solar Heat for Industrial Processes (SHIP) represents an incredibly promising market segment, showing significant growth in recent years. This growth is observed not only in the increasing number of applications but also in their scale, spanning various industrial sectors across Europe and beyond.

With its vast potential, this technology can play a key role in industrial decarbonisation efforts, contributing as such to net-zero targets.

Description of use

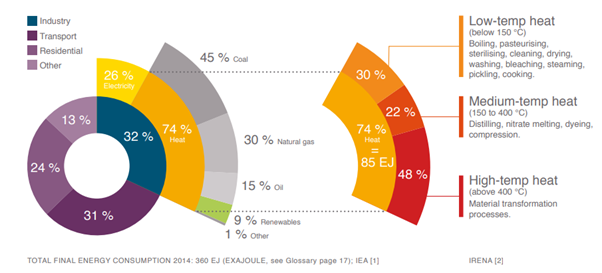

Heat is half of the energy consumed in Europe, with a substantial share utilised by industries producing goods essential to our society. While some industries demand extremely high temperatures for their processes, half of the current industrial activities rely on low or medium-temperature heat in the form of hot water or steam, that can be generated through solar thermal technology.

Industrial processes can use low and medium temperature for washing or dyeing textiles for example. The dairy sector uses heat for washing and pasteurization. Other industries, such as mining, can use it for leaching. Therefore, the use of low and medium temperature heat in industrial processes can be widely diverse. The food and beverage industry stands out as a key sector, showing substantial potential with existing case studies and numerous upcoming projects.

The choice of solar thermal collectors depends on the required heat temperature. For temperatures up to 150°C, technologies such as air collectors, flat plate collectors, and evacuated tube collectors are used. In cases where higher temperatures, up to 400°C, are required, concentrating solar thermal collectors like concentrating dishes, Fresnel collectors, and parabolic troughs can deliver.

Benefits

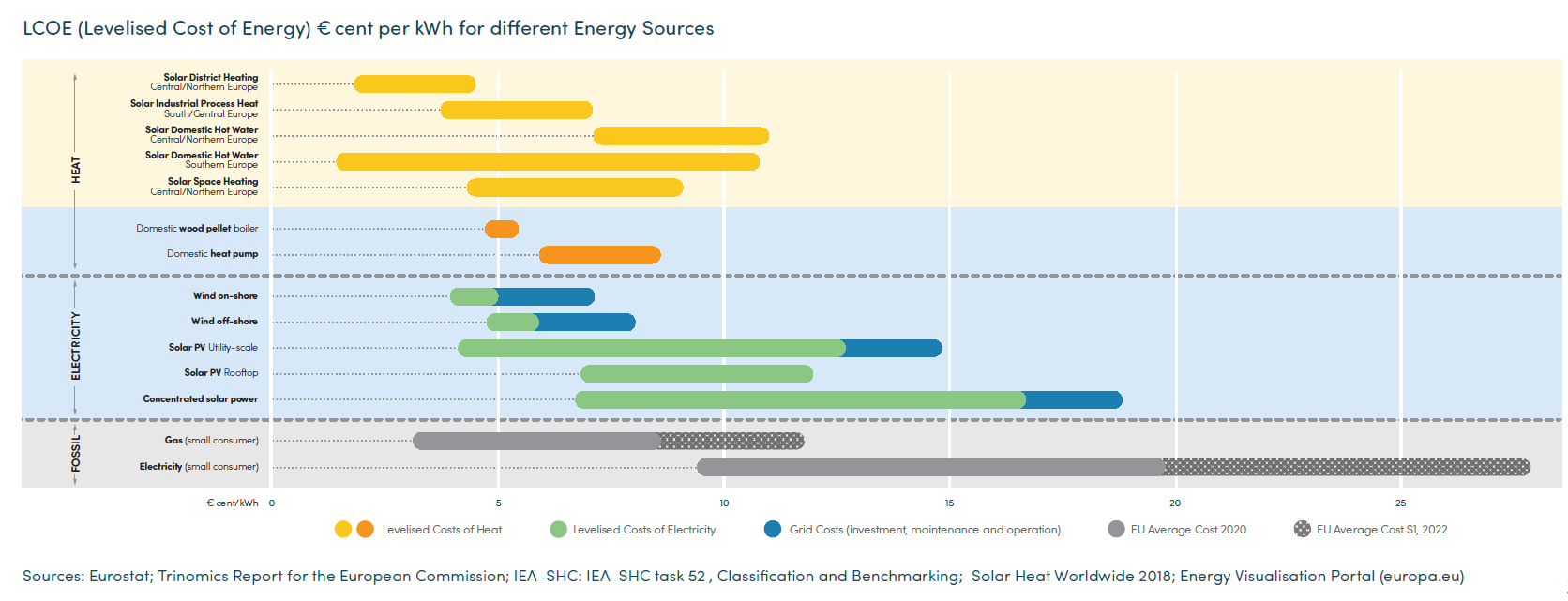

The benefits of solar thermal systems, in particular for such large systems, cover environmental, political and economic aspects.

Environmental benefits stem from the capacity to reduce harmful emissions. The reduction of CO2 emissions depends on the quantity of fossil fuels replaced directly or indirectly, i.e. when the system replaces the use of carbon-based electricity used for water heating. Depending on the location, a 1.4 MWth (2000 m²) system could generate the equivalent of 1.1 GWh/year, a saving of around 200 tonnes of CO2.

Political and economic benefits are associated with the potential savings in energy costs and the possibility of improving energy security by reducing energy imports. SHIP systems, being decentralised, contribute significantly to local job creation, covering roles from manufacturing and commercialisation to installation and maintenance of solar thermal systems. Notably, 99% of solar thermal capacity of the SHIP projects in the pipeline in Europe will be delivered by European companies.

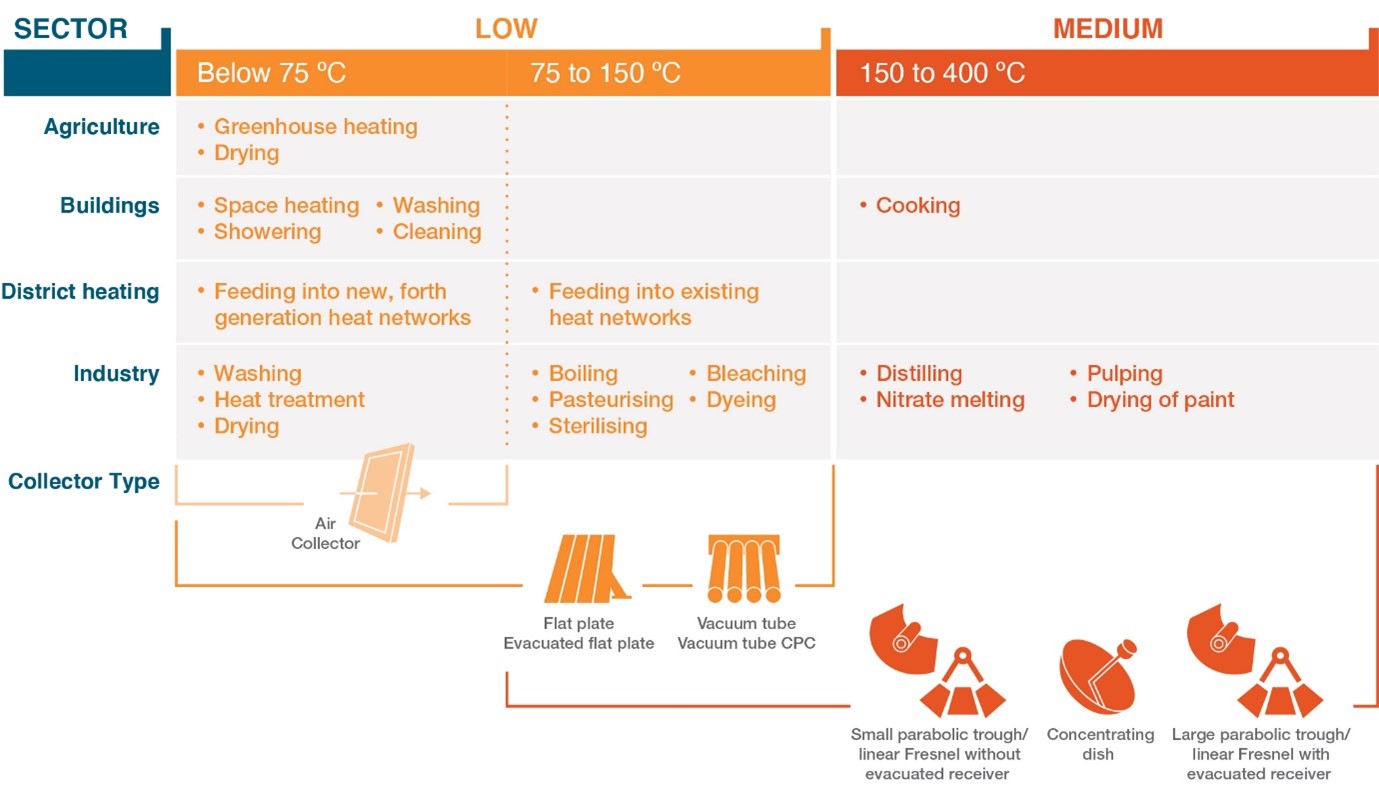

Regarding energy costs, and potential savings, there are three main aspects to consider that have a bigger impact on the comparable costs of the energy produced by a solar thermal system. These are the initial cost of the system, the lifetime of the system and the system performance. These factors depend on the location (affecting climate, insulation, taxes, cost of living, etc.) and quality of the system (affecting performance, lifetime and cost). This can vary significantly from country to country. Therefore, average investment costs for solar thermal systems can vary greatly from country to country and between different systems.

Examples of Solar Heat for Industrial Process plants across Europe

DAIRY SECTOR

Lactalis Group′s milk powder facility | Project by Newheat

- Location: Verdun, France

- Power Peak: 12.4 MWth

- Solar Collectors Area: 15,317 m²

- Storage Capacity: 3,000 m³

- Commissioned: November 2022

- Land Area: 5 hectares

- Annual Energy Delivery: Approximately 8,000 MWh per year

- CO2 Emissions Avoided: Around 2,000 tonnes per year

- Type of Collector/Supplier: Flat plate manufactured by Meriaura Energy

- Project Developer: Newheat

The Milk Powder Facility at Lacto Serum France, operated by the Lactalis Group, stands as an example of industrial processes decarbonisation with solar thermal. Commissioned in November 2022, this facility has a power peak of 12.4 MWth, covering a solar collector area of 15,317 square meters. Solar thermal energy is used at three integration points in the process: firstly, for preheating the main air inlet in the atomisation tower, ensuring optimal conditions for the milk powder production, secondly, for preheating the regeneration air from the dehumidification system, and finally for preheating of air used for ancillary processes.

Environmental Impact:

This solar thermal plant, the largest of its kind in France, has a substantial environmental impact. By annually delivering approximately 8,000 MWh of clean heat, it contributes significantly to reducing CO2 emissions, preventing around 2,000 tonnes of CO2 from entering the atmosphere each year.

Financial Structure – Heat Purchase Agreement (HPA):

The project’s financial support comes from various grants, including those from the French Energy Agency (ADEME), Région Grand-Est, and GIP « Objectif Meuse ». The plant operates under a Heat Purchase Agreement (HPA) and it was designed, developed, built, and now operated by Newheat. This 25-year HPA guarantees a consistent supply of renewable heat to the client, Lactoserum France, ensuring both energy security and environmental responsibility.

Learn more from our member’s website: Newheat

FOOD & BEVERAGE SECTOR

Martini & Rossi′s beverage production facility | Project by TVP Solar

- Location: Turin, Italy

- Power Peak: 400 kWth

- Solar Collectors Area: 600 m²

- Commissioned: February 2021

- Rooftop Area: 1000 m²

- Annual Energy Delivery: Approximately 390 MWh per year

- CO2 Emissions Avoided: Around 107 tonnes per year

- Type of Collector/Supplier: High-Vacuum Flat Plate manufactured by TVP Solar

- Project Developer: TVP Solar

Martini & Rossi, a renowned beverage production company based in Turin, Italy, has embraced solar thermal technology to enhance its sustainability efforts. With a solar power peak of 400 kWth generated from a solar collector area spanning 600 m², the solar thermal system contributes significantly to the energy needs of Martini & Rossi.

The integration of high-vacuum flat plate collectors, supplied by TVP Solar, shows innovative engineering. This system operates on a dual-use basis, providing steam at 3.7 barg (155°C) for crucial process heat during summer and hot water at 90°C for space heating during winter.

Environmental Impact:

The project’s impact is substantial, avoiding approximately 107 tonnes of CO2 emissions annually. This achievement aligns with Martini & Rossi’s commitment to environmental responsibility. With an annual energy delivery of about 390 MWh, this solar thermal installation underlines the company’s dedication to renewable energy solutions.

Learn more from our member’s website: TVP Solar

AUTOMOTIVE SECTOR

AVL Company′s automotive testing technology facility | Project by SOLID

- Location: Graz, Austria

- Power Peak: 2 MWth

- Solar Collectors Area: 3463 m²

- Storage Capacity: 70 m³

- Absorption cooling machine: 650 kWth

- Commissioned: 2017 (1480 m²), 2022 (1983 m², absorption chiller)

- Roof Area on Parking Garage and Test Facility: Approximately 5.000 m²

- Annual Energy Delivery: Approximately 1300 MWh heat per year; 250 MWh cold per year

- CO2 Emissions Avoided: Around 320 tonnes per year

- Type of Collector/Supplier: Flat Plate manufactured by Ökotec, Ensol, KBB

- Project Developer: SOLID

In 2017, AVL, a prominent company in the automotive sector, collaborated with SOLID, to address their energy requirements. After evaluating AVL’s energy demands, SOLID devised an innovative solution. A solar plant, covering an area of 3463 m², was installed along with a substantial storage facility of 70 m³. This solar thermal plant was complemented by an absorption cooling machine with a capacity of 650 kWth.

The solar collector field is also a roof, situated above the top floor of AVL’s parking deck. This dual-purpose installation not only harnesses solar energy but also provides shelter, maximising the utility of available space.

Environmental Impact:

Through this initiative, AVL significantly reduced its reliance on natural gas and district heating. The system not only fulfills their heating requirements but also supports process and space heating throughout the year. Moreover, during the summer months, the integrated absorption chiller caters to AVL’s cooling needs. By avoiding approximately 320 tonnes of CO2 emissions annually, AVL’s solar thermal integration significantly contributes to mitigating climate change.

Learn more from our member’s website: SOLID

AGRI-FOOD SECTOR

Vegetables greenhouse in Denmark | Project by GREENoneTEC

- Location: Ostervang, Dänmark

- Power Peak/day: 60 MWth

- Solar Collectors Area: 14.112 m²

- Storage capacity: 800 m³

- Commissioned: March 2015

- Land Area: 28 hectares

- Annual Energy Delivery: Approximately 7.000 MWh per year

- Type of Collector/Supplier: Flat plate manufactured by Arcon Sunmark

- Project Developer: Arcon Sunmark – Trade of GREENoneTEC

Growing vegetables in greenhouses in Denmark requires energy and heat – plenty of heat. Therefore, the heat exchange station at Østervang Sjælland can be compared with a medium-sized power plant.

The large solar field can produce up to 60 MWh on a sunny day, but since the energy must be used early the next morning, it will be stored in the 4.800 m3 large storage tank that can accommodate up to 5 days’ full solar production. When the control of temperature and humidity is properly managed, the use of chemical disease control can be reduced significantly, thereby making it possible to produce healthier and more environmentally friendly vegetables. The technique of controlling heat and moisture is used by most major players in the greenhouse industry, but usually, the heat comes from boiler plants based on coal or gas.

Learn more from our member’s website: GREENoneTEC

BREWING SECTOR

Birra Peroni brewing facility | Project by Absolicon

- Location: Bari, Italy

- Power Peak: 400 kWth

- Solar Collectors Area: 660 m²

- Commissioned: July 2023

- Land Area: 1700 m²

- Annual Energy Delivery: Steam – Approximately 366 MWh / Hot water – Approximately 496 MWh per year

- Type of collector/supplier: Concentrated Solar Collector Absolicon T160

- Project Developer: Absolicon

Starting in the summer of 2023, Birra Peroni, a part of the Asahi Group, embarked on a sustainable journey by commissioning Absolicon’s solar thermal field at their Bari production site in Italy. This pilot installation signifies a significant step toward decarbonising the brewery’s operations and aligns with Asahi’s goal of achieving carbon neutrality across its breweries by 2030.

Absolicon is providing its patented solar collector Absolicon T160 and plant integration. Birra Peroni will then buy the solar heat produced through a heat purchase agreement to run the brewing processes.

The solar collector Absolicon T160, with an operational temperature of up to 160°C heat and 8 bar steam, and plant integration provides Birra Peroni with solar heat to run the pasteurizer in the Bari brewery. The 400 kWth solar thermal field will cover part of the brewery’s annual thermal energy demand. During sunnier summer months, the collectors will ramp up their solar thermal contribution to satisfy a larger part of the thermal energy demanded for the pasteurizer process.

During a one-year evaluation, the solar installation will provide insights into how the concentrating solar technology can replace fossil fuels dependency in Birra Peroni plants. The evaluation period serves as basis to define the scope and detailed design for a potential bigger project, estimated at around 12 000 m2. At any point during this evaluation period, Birra Peroni has the flexibility to proceed with the larger project, fast-tracking their sustainability goals.

Learn more from our member’s website: Absolicon

Solar Heat Integration – Solutions for the decarbonisation of the pulp and paper industry

Cross-sectoral collaboration is key to the energy transition. In partnership with CEPI, we are proud to launch a factsheet on Solar Heat integration as a solution for the decarbonisation of the pulp and paper industry.

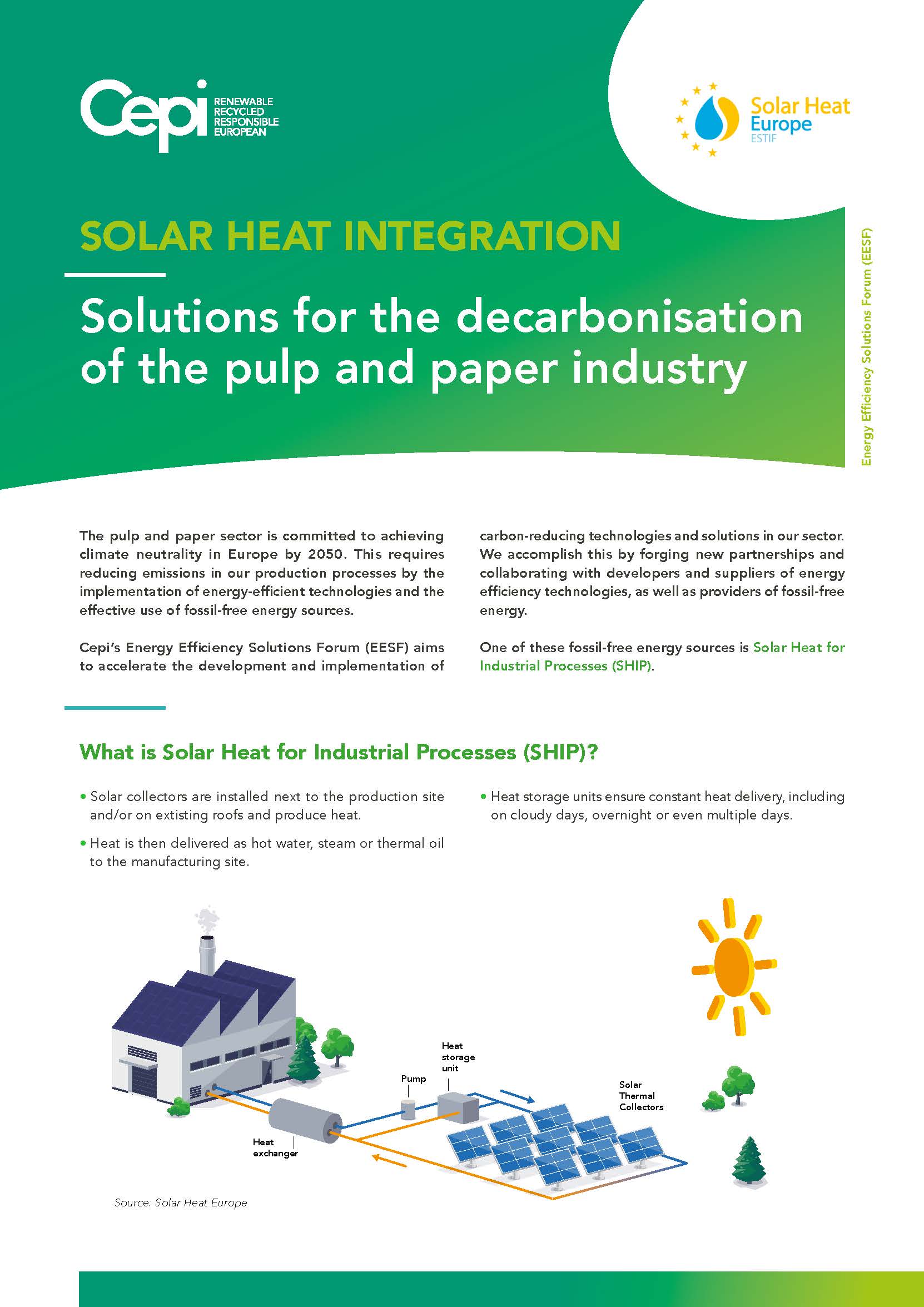

The pulp and paper sector is committed to achieving climate neutrality in Europe by 2050. This goal requires reducing emissions in their production processes through the implementation of energy-efficient technologies and the effective use of fossil-free energy sources.

One of these fossil-free energy sources is Solar Heat, specifically Solar Heat for Industrial Processes (SHIP) when applied in industrial contexts.

Solar heat technologies have significant potential to accelerate the decarbonisation of industrial processes, not only in the pulp and paper sector but across other industries as well. The advantages of these solutions include the renewable direct heat supply, price stability, or the ability to synergise with other energy solutions, to name a few.

Technical information

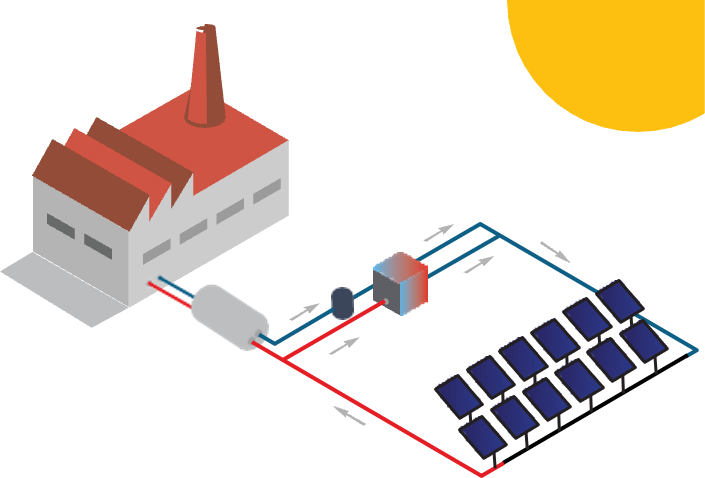

A system providing solar heat for industrial processes includes a large solar collector field, through which a working fluid circulates. This fluid is usually a combination of water and glycol and is transferred from the primary circuit to the process heat circuit via a heat exchanger. Whether the heat is transferred in the form of hot water, air flow or steam can be designed according to the requirements of the industrial process.

The system usually includes a heat storage unit, which is used to store the heat generated by the solar system (e.g. solar thermal collectors) and to make it available at a later time or to compensate for fluctuating heat demand.

For such systems, proper function and yield monitoring are critical to detect solar system failures early. A system is considered large if it exceeds 350 kWth (500 m²), although systems can range widely in size, depending on the application and process temperatures.

Temperature: Solar heat for industrial processes (SHIP) can go up to 400 °C.

Control: SHIP requires advanced control and metering, integrated with the overall management of the heat supply to industrial processes.

Operation & Maintenance: Medium level – the operating and maintenance requirements are in line with operating such large systems, either solar thermal or using other technologies. Correct operation is also required to maximise performance.

Additional resources

SHIP Plants Database

This database comprises over 400 solar thermal plants for industry across the world. It is now available in an interactive format.

Solar Industrial Heat Outlook

The outlook 2023-2026 presents the results of a worldwide survey showing an extremely positive trend for the next few years.

Solar Heat for Industry by Solar Payback

The leaflet comprises information about solar heat for industrial processes and testimonials from existing industrial users.

Solar Heat Worldwide Report

The report is published annually. Around 70 countries provide data to create a comprehensive evaluation of solar thermal worldwide.