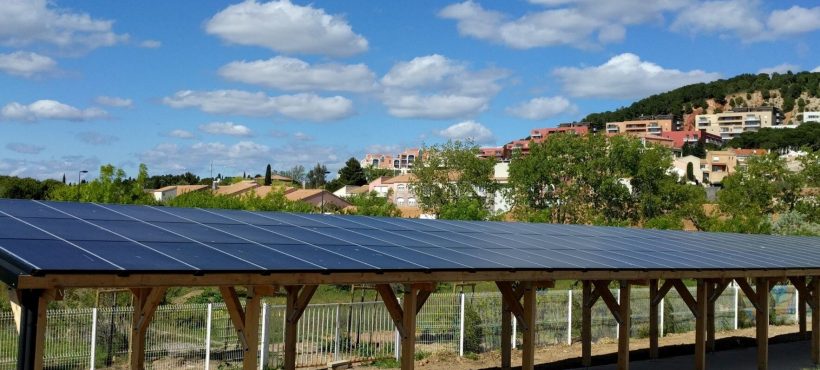

Featured picture credit: PVT system in the southern French town of Sète to supply heat and electricity to a public pool by Dualsun

Article written by Bärbel Epp, journalist at Solar Thermal World & CEO of Solrico.

Solar heat and solar electricity can make a good team: PV-Thermal (PVT) systems combine the production of both kinds of solar energy in one collector. This is a great advantage if roof space is limited. In the past few years, demand for this new type of solar technology has been growing. To support this upcoming market, the Solar Heating and Cooling Programme of the International Energy Agency (IEA SHC) launched a global research and communication project called “Task 60: Application of PVT Collectors and New Solutions in HVAC Systems”. IEA SHC Task 60 is organising an “International Seminar on the Status of PVT Systems”, in cooperation with the German Institute Fraunhofer ISE on the 16th of May in Freiburg, Germany, that is open to all interested stakeholders.

In several European countries the PVT market is picking up speed, particularly in France and Switzerland. “We see interest in new PVT solutions rising in several countries, as roof space is limited in urban areas,” said Jean-Christophe Hadorn, Manager of Swiss-based Hadorn Business Consulting and designated head of the new research project. In 2016 France installed a total of 620 PVT installations with a solar peak power of 1.7 MWel (around 17,000 m2) according to a market survey carried out by the French consultancy Observ’ER. Most of them supply warm air or warm water to heat single-family homes.

In Switzerland, water-driven PVT systems dominate the market: the panels have the same size and structure as PV modules, but a heat absorber is laminated, glued or clamped to the back side of the PV module. They are increasingly used in combination with ground-sourced heat pumps because the solar energy is used to re-heat the ground over the summer – to “regenerate” the heat source, as experts say. Researchers from the Swiss SPF – Institute of Solar Technology estimated that in Switzerland 300 PVT systems were operating at the end of 2016. Despite the growing demand, PVT is still a young technology. “A new emerging industry needs all-round support from research and marketing,” says Hadorn.

Generally speaking, PVT technology has the potential to be very efficient. PV modules use 15 to 20 % of the incoming solar energy, depending on the employed cell technology. The rest is lost in the form of heat. PVT elements use this “lost” energy to heat air or water. At the same time, taking away the heat from the panel cools the PV cells. This makes PV work more efficiently. But the output of electricity and heat depends on many variables. Therefore, Hadorn sees an urgent need to create more transparency regarding the output, costs and certification of different types of PVT systems. Therefore, the IEA SHC research project will gather monitoring data on heating and cooling systems using PVT systems. The goal is to compare the monitoring data with the simulated output, so calculation methods can be optimised.

Scientists of the Swiss research institute SPF have already made some evaluations: PVT collectors in central Switzerland usually produce an annual electric yield of about 160 kWh/m². The hot water production depends greatly on the application: the lower the required temperature, the higher the energy output. If domestic hot water (for showers, etc.) is heated directly, around 150 kWh per m2 collector area can be gained annually. If the water is only pre-heated, 250 kWh/m² per year is possible. If boreholes of ground-sourced heat pumps are regenerated, annual solar yields of 300 to 400 kWh/m² can be gained.

How much electricity production benefits from the cooling effect of PVT varies by the operating temperature on the heat side. Low-temperature applications lead to the highest efficiency gain: they typically show a 5 % increase in annual solar electricity output compared to standard PV systems.

A new emerging industry

Hadorn notices a great interest by manufacturers in this IEA SHC project so far. In the past three years, a growing number of specialised suppliers with approved technologies are dominating the European PVT markets. One of them is French-based Dualsun, which is participating in Task 60. It has realised more than 500 PVT projects in Europe according to company information. Dualsun has published monitoring data for two 300 m2 PVT fields for commercial swimming pools in the south of France, which match well with simulation results (see table). This shows that the co-production of heat and electricity can be reliably predicted.

| PVT location | Annual solar heat yield (TRNSYS simulation) kWh/a | Annual solar heat yield (measured) kWh/a | Difference | Annual solar electricity yield (TRNSYS simulation) kWh/a | Annual solar electricity yield (measured) kWh/a | Difference |

| Sète | 81,354 | 82,100 | 2 % | 55,826 | 59,113 | 5.9 % |

| Perpignan | 97,077 | 119,870 | 23 % | 60,535 | 63,942 | 5.6 % |

Simulated and monitored annual yields of two PVT systems (300 m2 area each) installed in public swimming pools in France, – Source: Dualsun

Fraunhofer ISE and Task 60 coordinator Hadorn invites all interested stakeholders to the “International Seminar on the Status of PVT Systems“ on 16th of May in Freiburg, Germany. The one-day event will be held in English. Experts from the research project will present latest insights on market and technology development. For more information and updates please check the Task 60 web site: http://task60.iea-shc.org/event?EventID=5017 and register online.

IEA SHC is an international research and information programme on solar heating and cooling technologies. Around 200 experts from 21 countries and five organisations cover a wide range of topics from urban solar planning to future storage tank concepts and the integration of large-scale solar fields in district heating and cooling networks. “Application of PVT collectors and New Solutions in HVAC Systems” or simply “PVT Systems” is one of eleven research projects which are called “Tasks” within the IEA SHC Programme. The PVT task will run until the end of 2020.

|

PVT Technologies

|

|

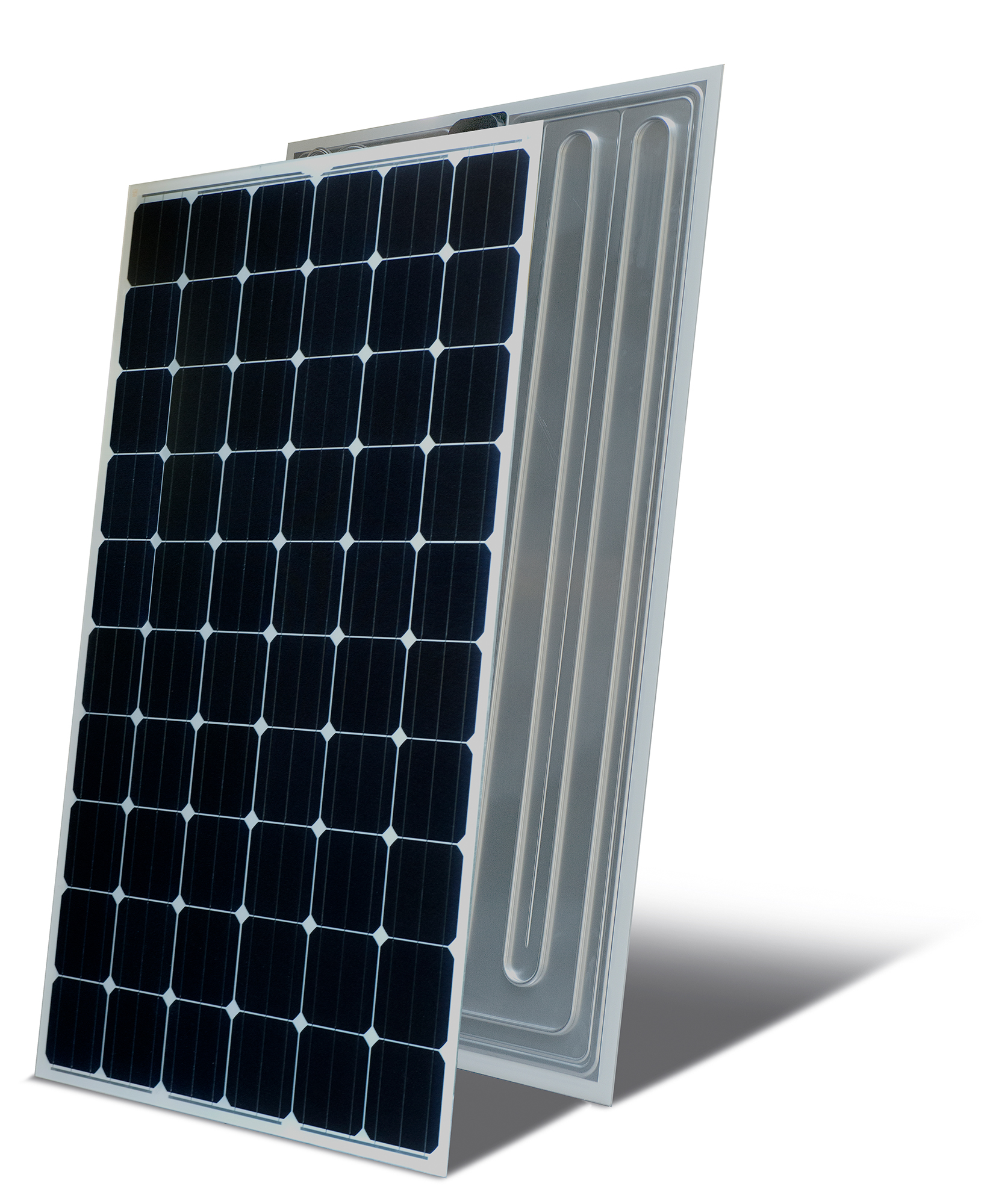

| PVT without insulation

The structure is usually the same as a PV module. The PV cells are laminated between a glass on the front side and a polymer sheet on the back side. A heat absorber is laminated, glued or clamped to the back side of the module. The absorber can be made of metal or polymer material and it can be filled with air or liquid.

Evaluation: Relatively simple construction, but higher heat losses and therefore lower temperatures of the heat transfer fluid

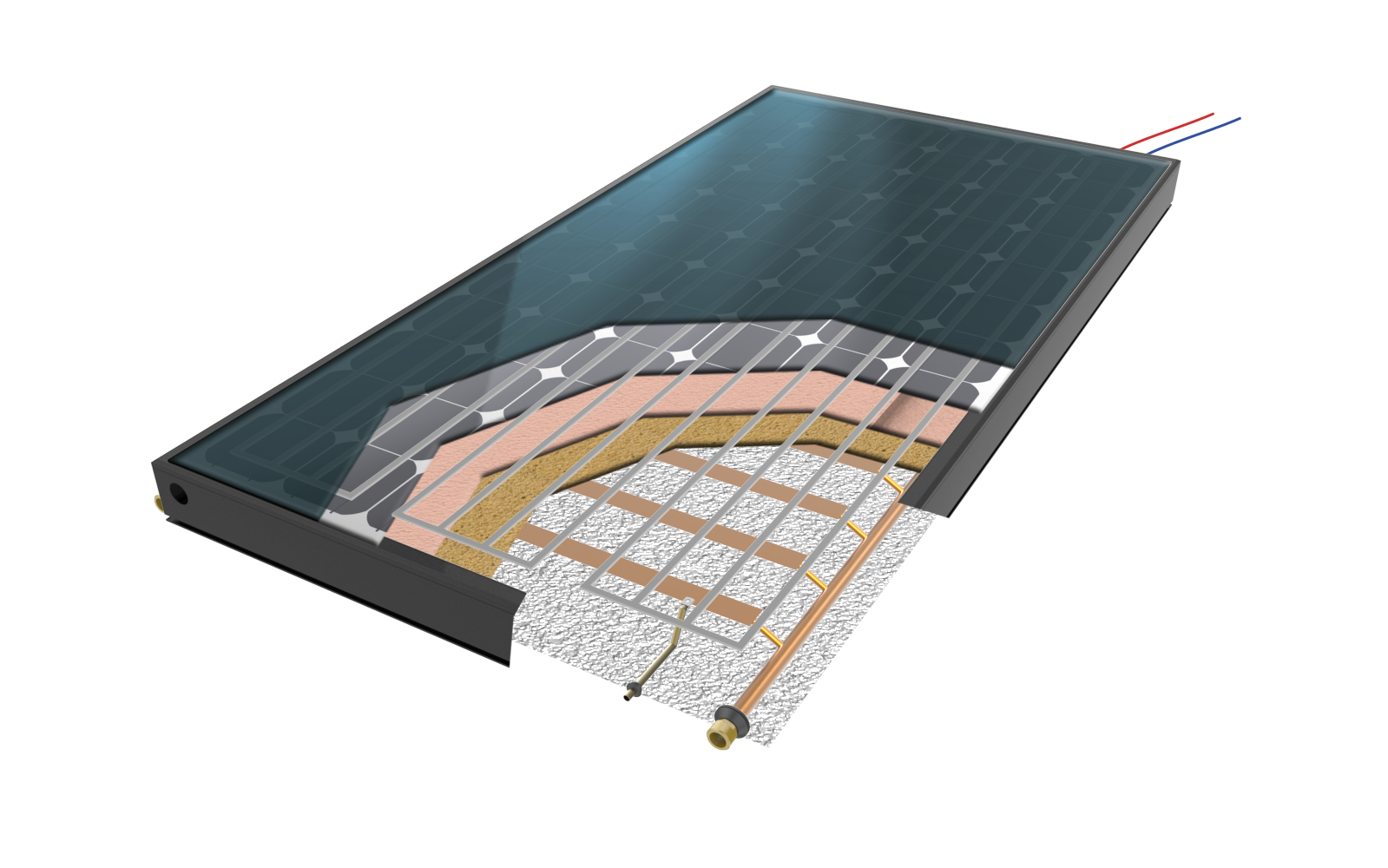

PVT with insulation The structure is the same as above, but includes an insulation layer at the back side of the heat exchanger and an outside casing.

Evaluation: More complex construction, but lower heat losses and therefore higher temperatures of the heat transfer fluid |

Photo: Meyer Burger (Switzerland) AG

|

Photo: Solimpeks

Photo: Solimpeks

Leave a Reply